Faggiolati Pumps S.p.A

Faggiolati pumps working according to ISO 9001:2008, UNI EN ISO 14001:2004 norms, paying utmost attention and care to the product (the motors, up to powers of 18 kW, are certifi ed according to anti explosion legislation EN 13980 ATEX).

Faggiolati pumps also supply submersible mixers, water aerators and ossi-jets, electronic instruments, several accessories for lifting plants.

Mixers  | DESCRIPTION Faggiolati's mixers are projected for optimal mixing, homogenising and agitating operations in civil and industrial waste-water purification plants. The high performance ratings allow a considerable reduction in running costs. The non-clogging propeller profile, combined with an accurate projection, guarantees optimal running condictions with absolute reliability.Submersible mixers, rugged in construction, watertight electric motors accomodated in compartment, connected, by shafts of reduced lenghts, to the impellers situated by the interposition of oil chamber between the hydraulic side and the electric motor.Asynchronous, threephase electric motors, squirrel cage type, IP 68 protection, class H insulation. They are designed for S1 (continous) service, with a max overloading up to 10% environmental cooling at temperature 40oC. Starts par hour up to 15. Motors cooling comes through thermic exchange with surrounding fluid. motor housing Cast iron EN-GJL-250; propeller Stainless steel AISI 316; electric cable Neoprene H07RN/F; shaft Stainless steel AISI 420; o-rings Nitrile; bolts A2 class; mechanical seal Silicon Carbide/Silicon Carbide. motor housing Stainless steel AISI 316; propeller Stainless steel AISI 316; electric cable Neoprene H07RN/F; shaft Stainless steel AISI 316L; o-rings Viton; bolts A4 class; mechanical seal Silicon Carbide / Carbide /Viton. |

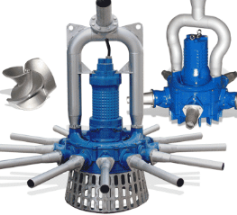

Ossi-Mix  | DESCRIPTION The OSSI-MIX (OM) system is a new development in the sludge aeration machines sector. The System is based on the use of a special hydraulic system with a 3-channel centrifugal impeller, which works in a special 12-outlet diffuser. The outlet of the pump is thus spread among the 12 nozzles that deliver the sludge to be aerated into 12 individual mixing chambers. In these chambers the sludge is contacted with the air supplied by a compressor, the air-sludge contact occurs in an high turbulence annular conduit. The OM system has been designed for a long operational life which translates in low operating costs. All parts subject to wear can be replaced easily from the edge of the tank with the use of simple tools. |

Arial Jet  | DESCRIPTION AJ submerged aerators are an extremely flexible and versatile airing system for the treatment of waste-water and in every case air/water mixing is required . Elevated oxygen transfer values, low noise levels, increased reliability, low cost and rapidity of installation are just some of the advantages that our AJ submerged aerators offer. These aerators are frequently used in waste water treatment plants, especially during homogenisation and equalisation, pre-airing stages, biological oxidation, oxidation-nitrfication, sludge stabilisation and post-airing stages. AJ radial submerged aerators can be utilised for the flotation of greases, oils and solids, at the relevant stages of flotation. |

Ossi-Jet  | DESCRIPTION The Ossi-jet system offers an excellent alternative for aeration and mixing of any civil or industrial liquid. In order to satisfy any type of requirement, it is possible to couple various pumps to various ejectors. Ossi-jet is particularly recommended for biological waste-water treatment plants, chemical waste treatment plants and fish farming. The different type of impellers and ejectors offered by the Ossi-jet system optimise the following processes: -oxidation; -CO2 neutralisation; -Ozonisation / mixing; -Foam reduction. |